|

Shanghai Jiecon

Innovator of Photocatalyst Technology

Leading the New Era of Fabric Deodorization

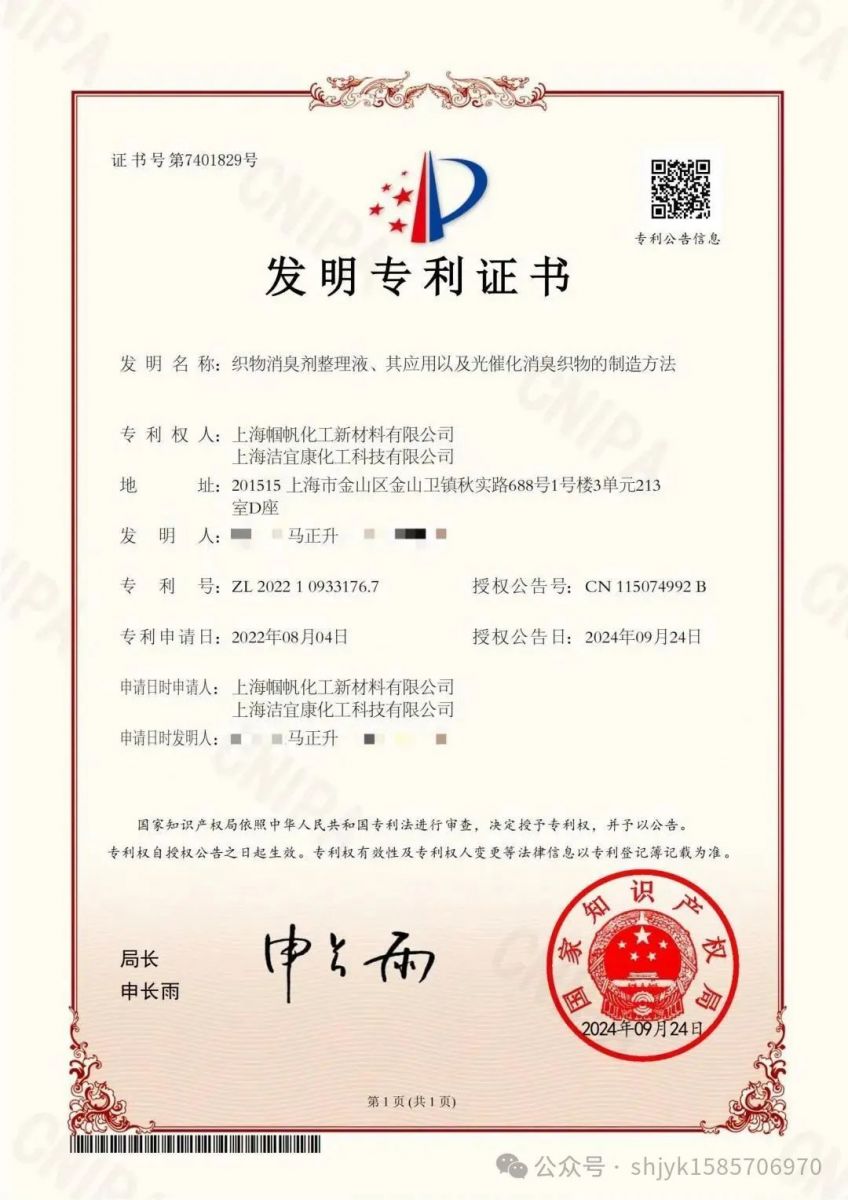

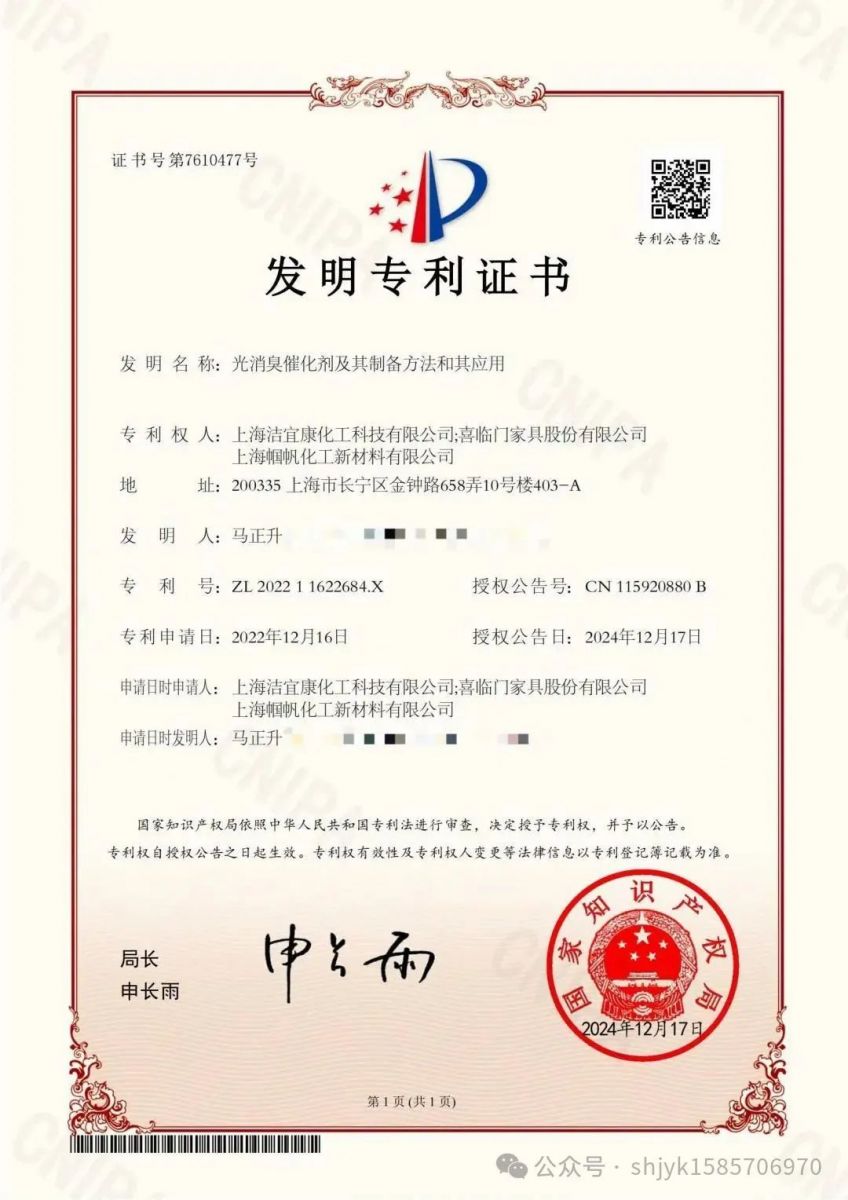

Relying on the profound technical accumulation from years of in-depth engagement in the industry and adhering to the pioneering and innovative spirit, Shanghai Jiecon Chemicals Hi- Tech Co., Ltd. independently developed the invention patents of "Fabric Deodorizing Agent Finishing Liquid, Its Application and Manufacturing Method of Photocatalytic Deodorizing Fabric" and "Photodeodorizing Catalyst, Its Preparation Method and Its Application", which are exemplary achievements of the deep integration of technological innovation and industrial practice.

These two patents not only set a new benchmark for technological development in the textile industry, leading it to a higher level, but also, with their outstanding performance, truly meet consumers' urgent demand for a healthy and fresh living environment, bringing the public a long-lasting and high-quality fresh living experience. Photocatalyst (photo-catalyst) technology has been widely applied in the civilian sector in developed countries and regions such as Japan. Its active ingredients, upon absorbing ultraviolet rays from sunlight or artificial light sources, undergo oxidation and reduction reactions, generating hydroxyl radicals and superoxide radicals, which can react with organic substances, breaking down molecular bonds (C-C, C-H, C-N, C=O, N-H, etc.) of organic compounds and decomposing harmful substances and microorganisms in the air into harmless carbon dioxide and water.

The working mechanism is shown in the following figure.

The following is the performance test result of the developed photocatalyst finishing agent applied to textiles.

01 Photocatalytic antibacterial performance under visible light (Chinese National Standard)

According to the Chinese national standard GB/T 30706-2014 "Test Methods and Evaluation of Antibacterial Materials and Products under Visible Light Irradiation", the antibacterial rates of Staphylococcus aureus and Escherichia coli of the tested samples were both 99%, and the light contribution rate was 67%. The test shows that the fabrics treated with the photocatalyst finishing agent developed by our company have good antibacterial performance under visible light conditions and good washing resistance.

Note: Please refer to the test report for the test conditions.

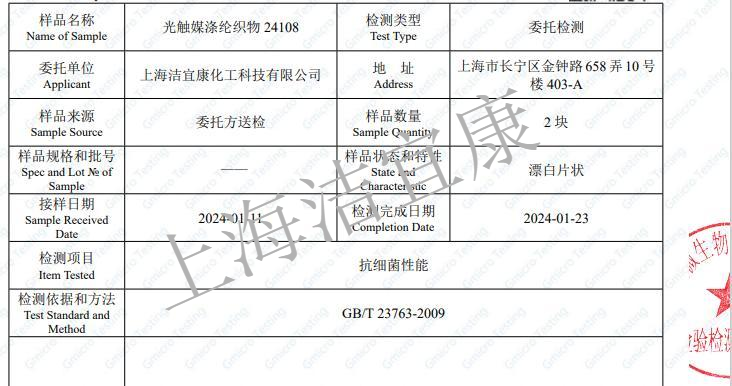

02 Antibacterial Performance of Photocatalyst under Ultraviolet Conditions (Chinese National Standard)

According to the Chinese national standard GB/T 23763-2009 "Evaluation of Antibacterial Performance of Photocatalytic Antibacterial Materials and Products", the antibacterial rate of Staphylococcus aureus of the tested samples is greater than 99%, and the antibacterial rate of Escherichia coli is 99% (with the contribution of ultraviolet light being 80%). The test shows that under ultraviolet conditions, it has more obvious antibacterial performance and good washing resistance.

Note: For test conditions, please refer to the test report.

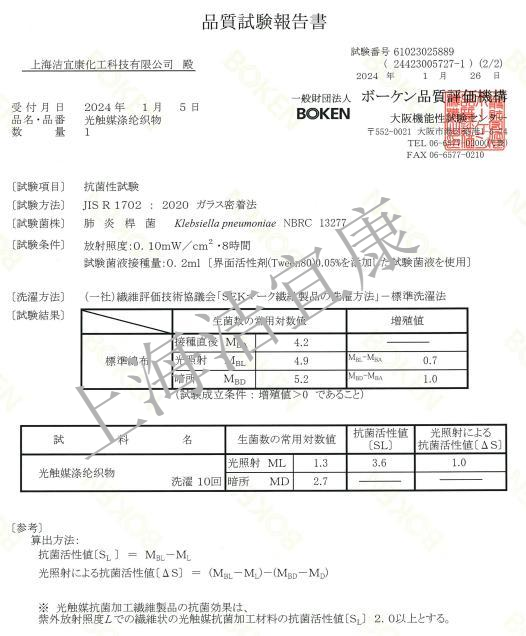

03 Photocatalytic Antibacterial Performance under Ultraviolet Conditions (Japanese Standard)

According to the Japanese standard JIS R 1702:2020, the antibacterial activity value of Staphylococcus aureus on the tested samples under the ultraviolet condition was 3.6, with a light contribution rate of 1.9; the antibacterial activity value of Klebsiella pneumoniae was 3.6, with a light contribution rate of 1.0. The test results show that the fabrics treated with the photocatalytic finishing agent developed by our company have obvious photocatalytic activity, can produce good antibacterial effects, and have good washing resistance.

Note: For the test conditions, please refer to the test report.

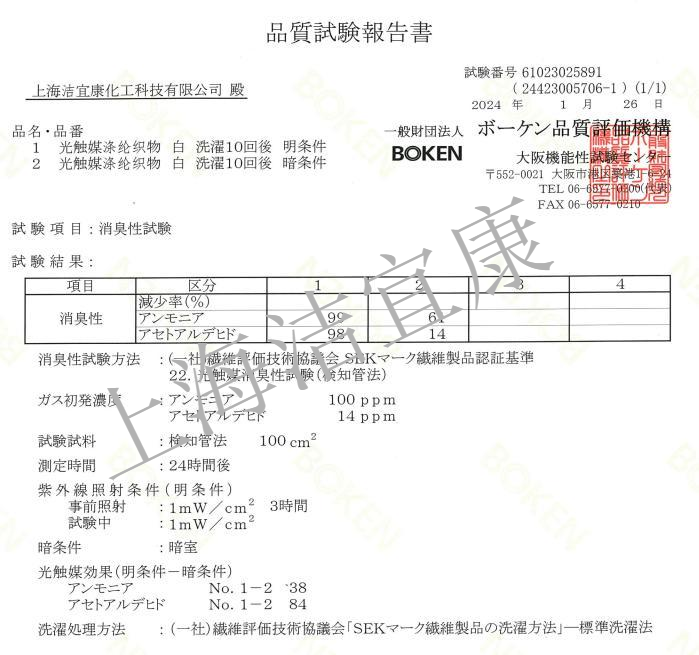

04 Photocatalytic Deodorization Performance under Ultraviolet Conditions (Japanese Standard)

According to the Japanese standard: (The Fiber Evaluation Technology Association) SEK MARK Fiber Product Certification Standard 22. Photocatalytic Deodorization Test (Horizontal Tube Method) (Under Ultraviolet Conditions), the ammonia deodorization rate of the tested sample under bright conditions was 99%, and the acetaldehyde deodorization rate was 98%; the photocatalytic effect on ammonia was 38%, and the photocatalytic effect on acetaldehyde was 84%. The test results show that the fabrics treated with the photocatalytic finishing agent developed by our company have obvious photocatalytic activity, can produce a good deodorization effect, and have good washing resistance.

Note: For test conditions, please refer to the test report.

05 Photocatalyst Antiviral Performance under Ultraviolet Conditions

According to ISO 18184:2019 "Textiles - Determination of Antiviral Activity of Textiles", the antiviral activity rate of the test sample against Influenza A virus H1N1 is greater than 99%. The test shows that under ultraviolet conditions, it has more obvious antiviral performance and good washing resistance.

Note: For test conditions, please refer to the test report.

06 Photocatalytic negative oxygen ion generation performance under ultraviolet conditions

According to the Chinese national standard GB/T 30128-2013 "Textiles - Detection and Evaluation of Negative Ion Generation", the negative oxygen ion generation of the test sample reached 631. The test shows that under ultraviolet conditions, it has obvious negative oxygen ion generation performance and good washing resistance.

Note: For test conditions, please refer to the test report.

These two patents not only set a new benchmark for technological development in the textile industry, leading it to a higher level, but also, with their outstanding performance, truly meet consumers' urgent demand for a healthy and fresh living environment, bringing the public a lasting and high-quality fresh living experience.

The two photocatalyst patent technologies of Shanghai Jiecon Chemical Technology Co., Ltd. not only represent a technological revolution in the textile industry but also profoundly interpret a healthy lifestyle. From patent endorsement to market application, from laboratory innovation to industrial implementation, Jieyikang uses the power of science and technology to turn every piece of fabric into an "invisible guardian" for health. On the path of green development, Jiecon is using photocatalyst as a pen to write the future chapter of the textile industry.

|